Field First: HIT and Max Power Checks with ModernHawk

The UH-60 Blackhawk has quickly demonstrated its usefulness and power in the utility world. Since the first Blackhawks came to the civilian market, ModernHawk has been a partner with companies looking for ways to more efficiently track and manage their aircraft maintenance programs. ModernHawk makes tracking engine performance simpler than ever before through easy-to-use tools accessible on any mobile device.

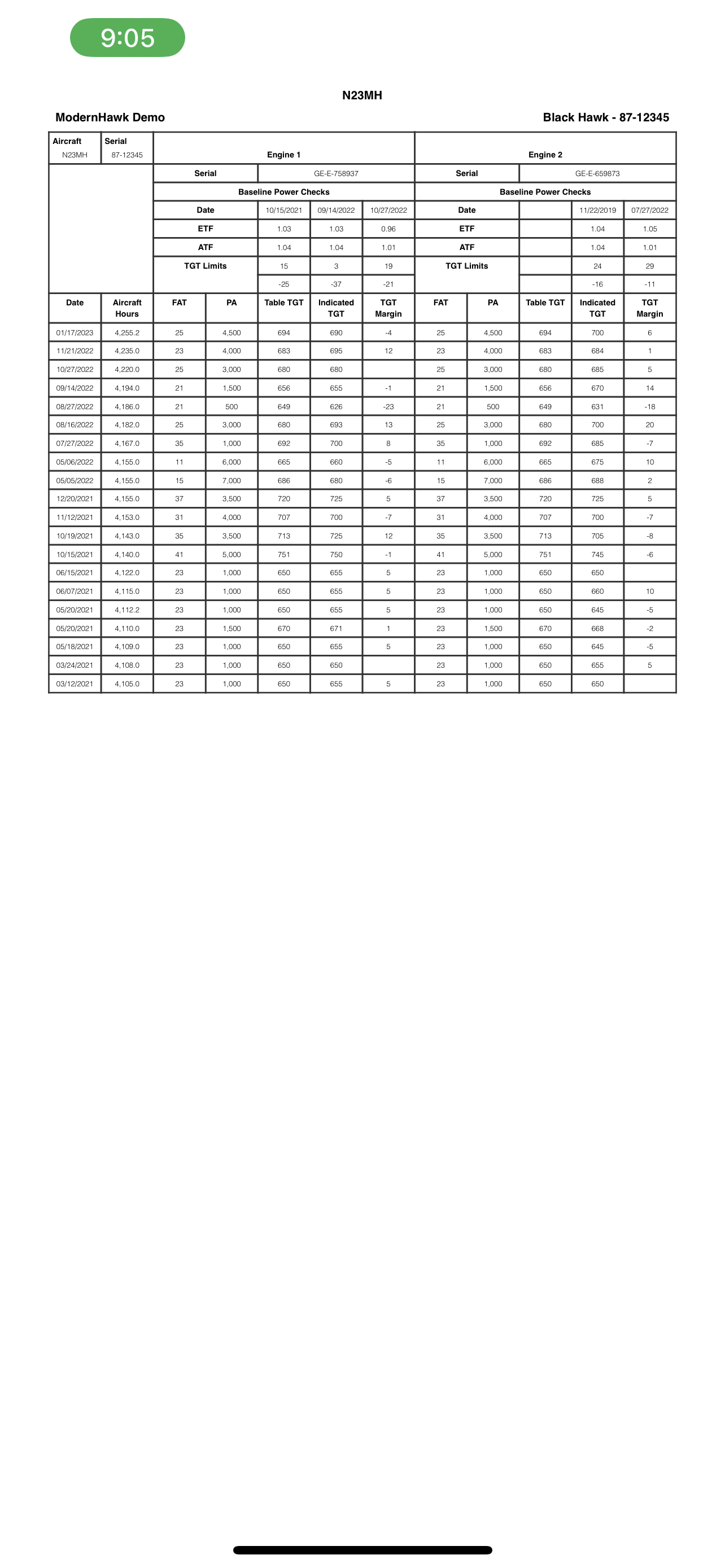

UH-60 engine performance monitoring is conducted through the daily Health Indicator Test (HIT) Check as well as the Baseline / Max Power Check which is conducted following the replacement of an engine or following certain maintenance actions. ModernHawk features HIT and Max Mower check tracking to more easily monitor engine performance across an aircraft operator’s fleet. HIT Check data can also exported easily if needed for contract requirements.

HIT Checks

“A malfunctioning engine anti-ice and engine inlet

antiice system may result in power losses as

much as 40% maximum torque available at 30

minute TGT demands”

HIT checks are usually conducted daily to determine if aircraft performance meets previously established baseline parameters. Dirty compressor blades can reduce engine performance, leading to higher TGT values and eventually lead to a failed HIT check. HIT checks also ensure the aircraft bleed-air system is operating properly and there are no leaks or malfunctions which could reduce power during critical modes of flight. For example, a malfunctioning Anti-Ice Start Bleed valve can reduce maximum torque available by as much as 40% at 30-minute TGT demands. The check also can be used to ensure that allowable levels of torque stiction (not greater than 5%) are present.

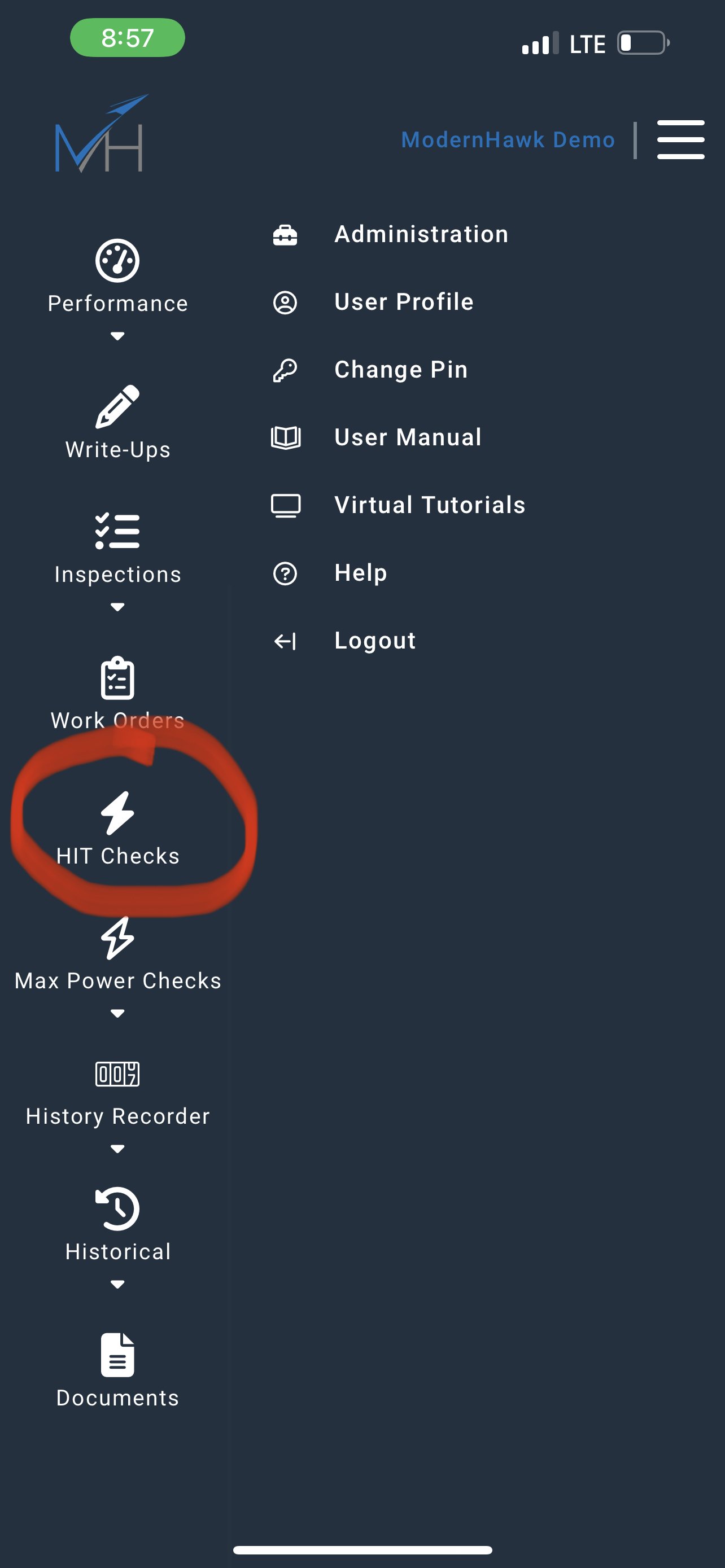

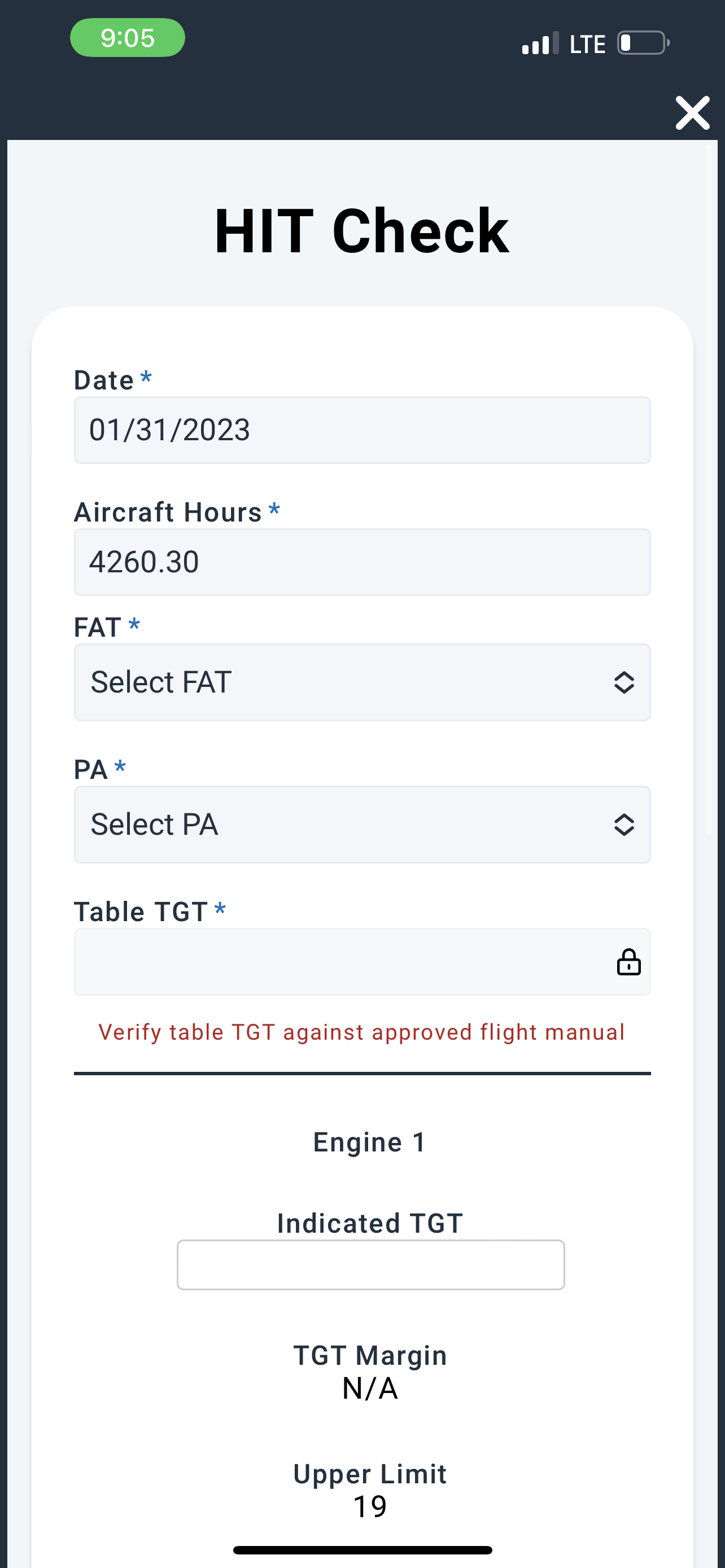

UH-60 aircraft in ModernHawk are provided with a HIT Check menu. On the dashboard, select the aircraft you wish to enter a HIT Check for, then select “HIT Checks”. The HIT Page will appear with the HIT Log, print icon, and “Enter New HIT options.” Select “Enter” to input a HIT Check. Enter aircraft hours and select free air temperature (rounded up to the nearest odd value) and pressure altitude (rounded to the nearest value). The target table TGT derived from the aircraft flight manual will then be displayed.

Following the HIT check, Enter the noted TGT value into the “Indicated TGT” block for Engine 1. The TGT Margin will then appear with the upper and lower limits as well as the pass / fail result and Engine Torque Factor displayed below. If the indicated TGT falls within the upper and lower limits and all bleed-air checks are successful, then then your engine has successfully passed the HIT check. If it does not pass any of the above criteria, do not fly the helicopter.

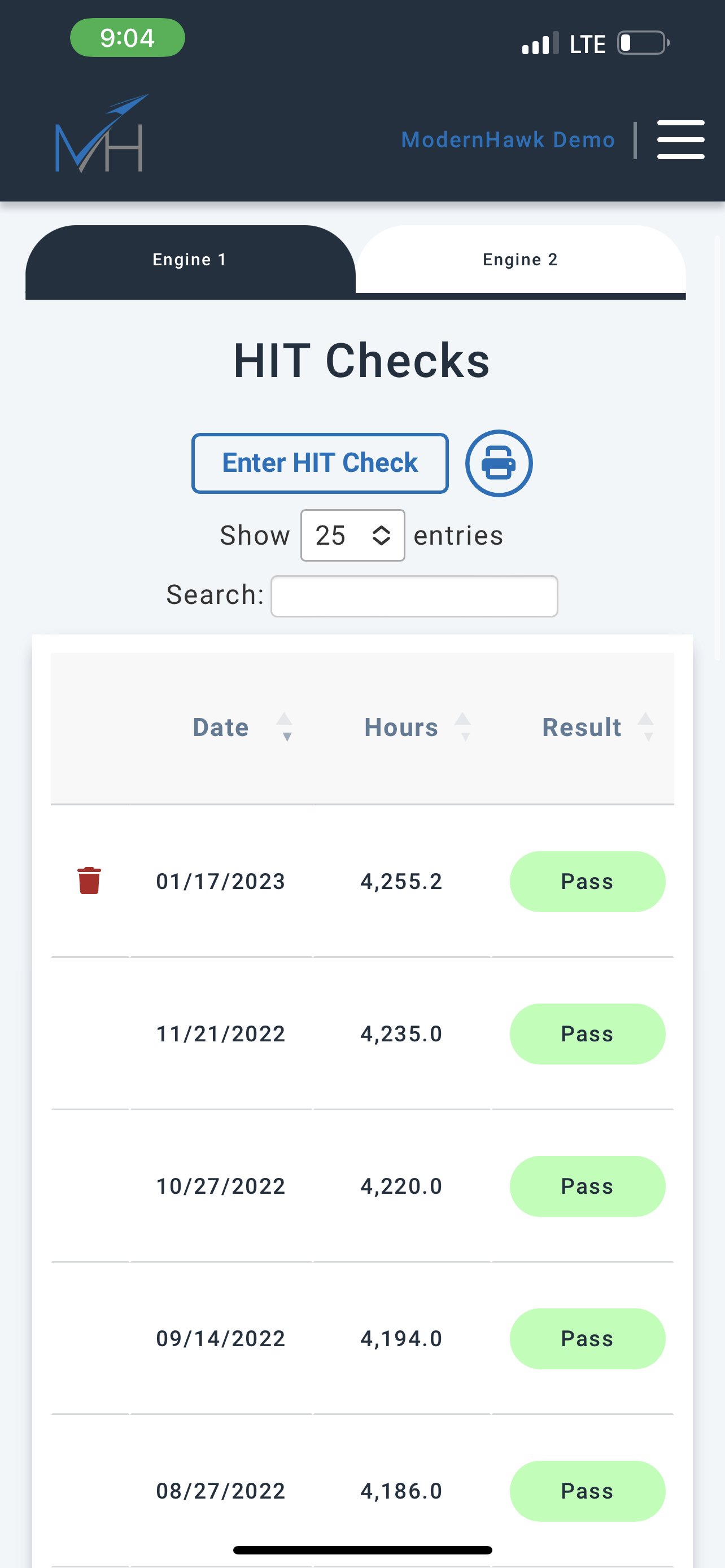

Once the second engine has been passed you can save the completed HIT check by entering your PIN number at the bottom of the screen and tapping “Save.” The check will be saved in the HIT log. HIT logs can be printed by tapping on the “Print” icon in on the HIT page. Enter the number of HIT Checks you would like to print and select the following link. A PDF will be generated , which you can print locally from your device.

In the field, it is important to monitor engine performance trends to ensure the aircraft is operating as efficiently as possible. Multiple or consecutive HIT checks within 5 degrees of the limit may indicate a change in engine performance. With ModernHawk, data on engine performance can be checked by multiple employees within an organization and monitored across the fleet. Green and red coded “Pass” / “Fail” indications also appear on HIT check logs to quickly flag aircraft which have failed their HIT check.

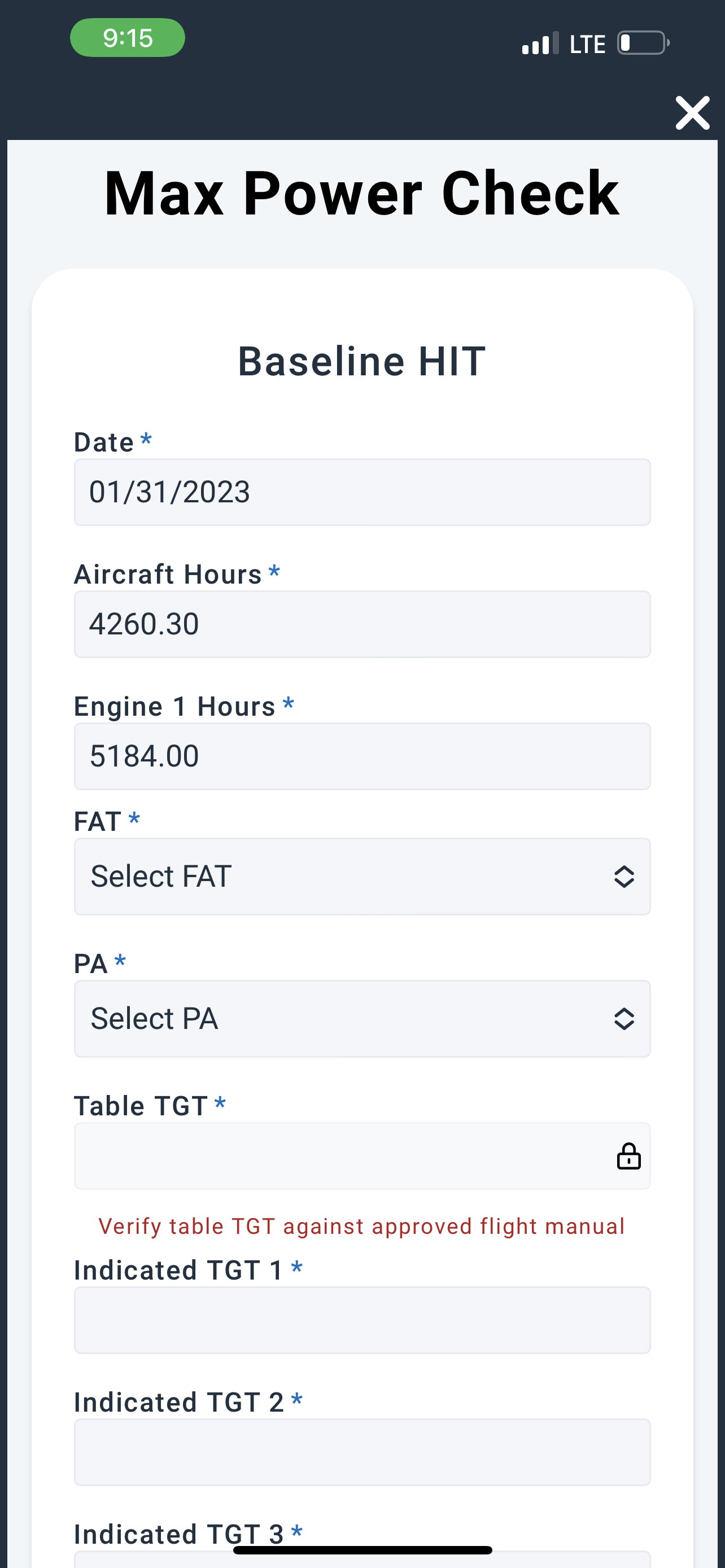

Engine Baseline Procedures

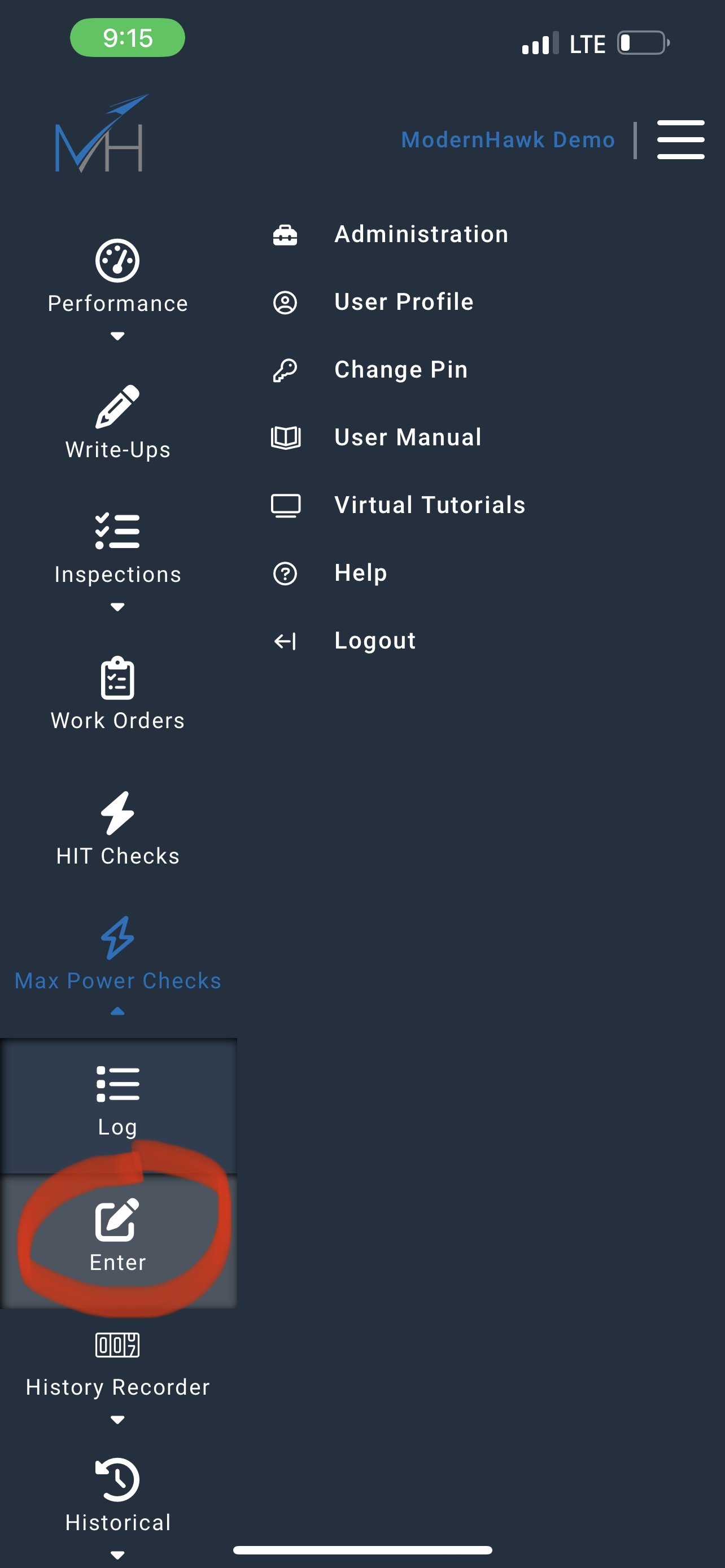

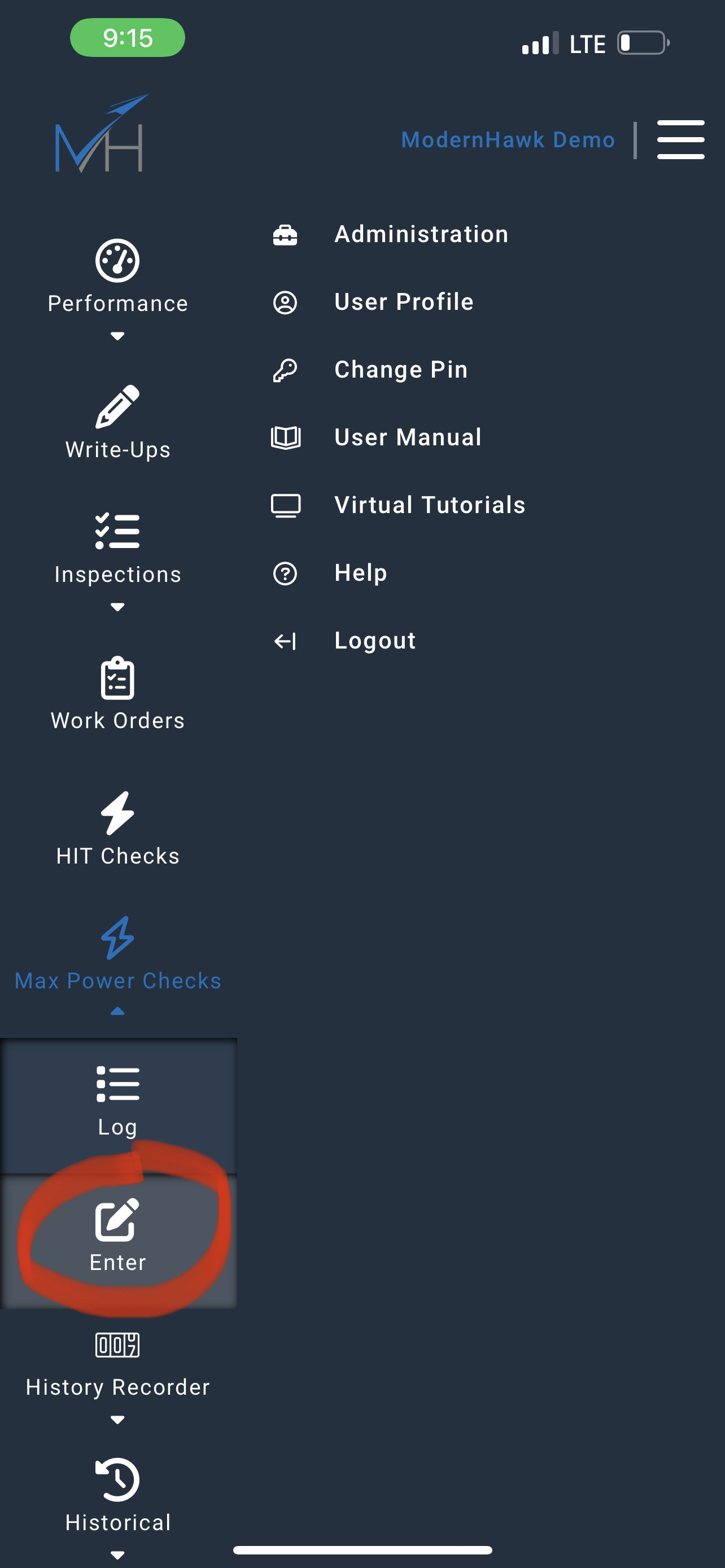

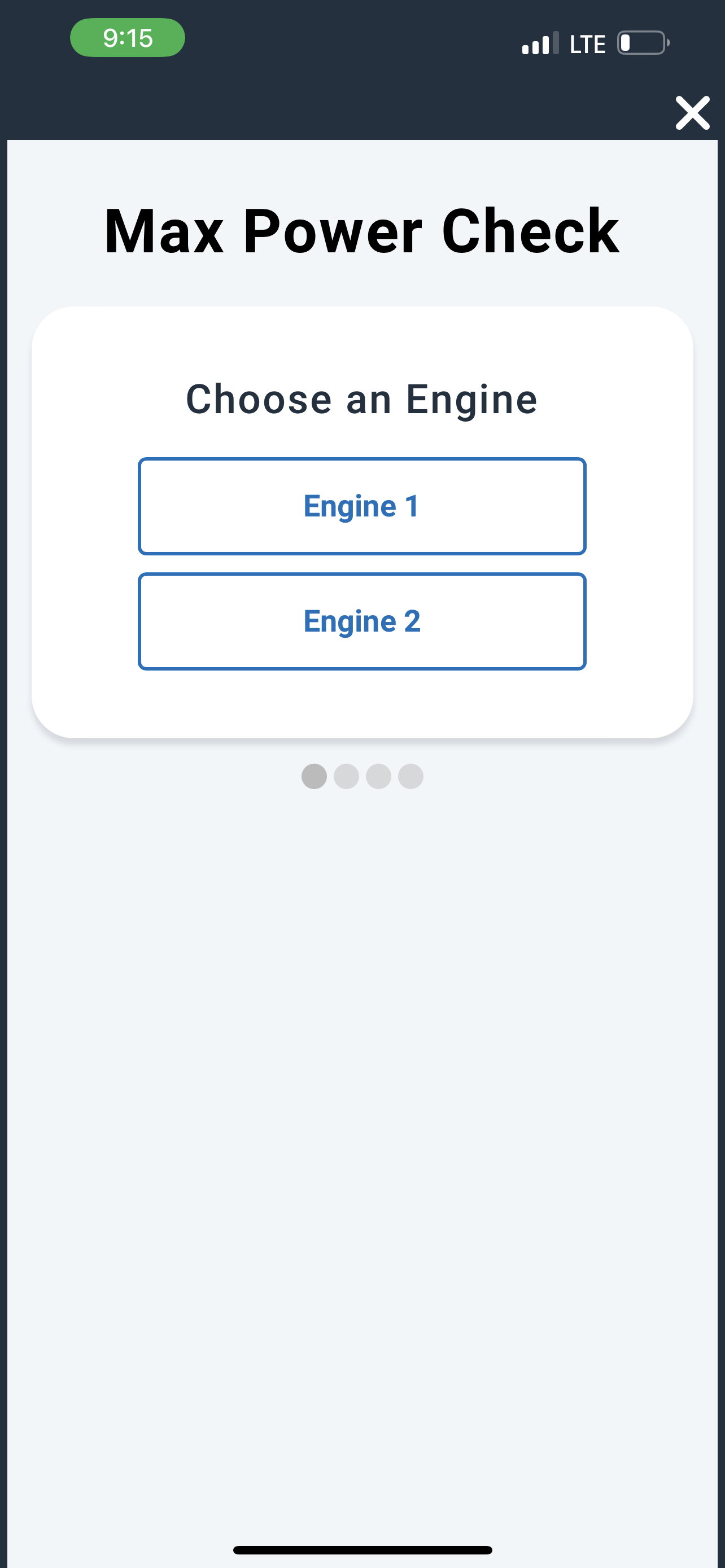

A HIT Baseline check is simply an average of three HIT checks and is conducted prior to a Max Power check to establish a value for the aircraft’s current engine performance. ModernHawk stores Baseline data in the Max Power section. Select “Enter” in the Max Power menu. The baseline data can be saved on the second page of the Max Power check. Enter the FAT and PA data and a table target TGT will appear. Conduct three HIT checks and record the TGT value for each check. Reset the collective after each 30 second period before obtaining another reading. Enter the three TGT values in the appropriate blocks. ModernHawk will automatically provide a TGT margin value as well as an upper and lower limit. Once the Baseline / Max Power check has been saved, future HIT checks will reference this new baseline value.

Maximum Power Checks

Max Power Checks are conducted to determine maximum engine performance during flight. Minimum requirements for Max Power checks are a .85 Engine Torque Factor for a single engine and an average of .90 Aircraft Torque Factor for both engines combined. Best practice is to maintain ETF/ATF values at a 1.0. For detailed Max Power Procedures for each model of aircraft / engine, refer to TM 1-1520-237-MTF.

Here are some general considerations to keep in mind regarding Max Power Checks:

· Max Power checks are required following the installation or reinstallation of an engine, or for the removal and replacement of certain engine components such as an HMU. Refer to the approved engine manual to determine when a Max Power Check is required following a maintenance action.

· Ground checks such as an ECU/DEC Lockout Check, Acceleration / Deceleration Check, or Torque Matching / Load Sharing Check may also be required to confirm proper operation of engine systems and components. Ensure this is completed before takeoff to limit the possibility of failure, especially during the Max Power Check.

· Environmental factors may impact whether TGT limiting may be reached. If rotor droop occurs prior to reaching the 700/701C/701CDD TGT limit, the engine may be Ng limited. This temperature range is generally below 0 degrees Celsius to -20 degrees. If Ng limiting is noted during the check, follow the procedure listed in 237-MTF.

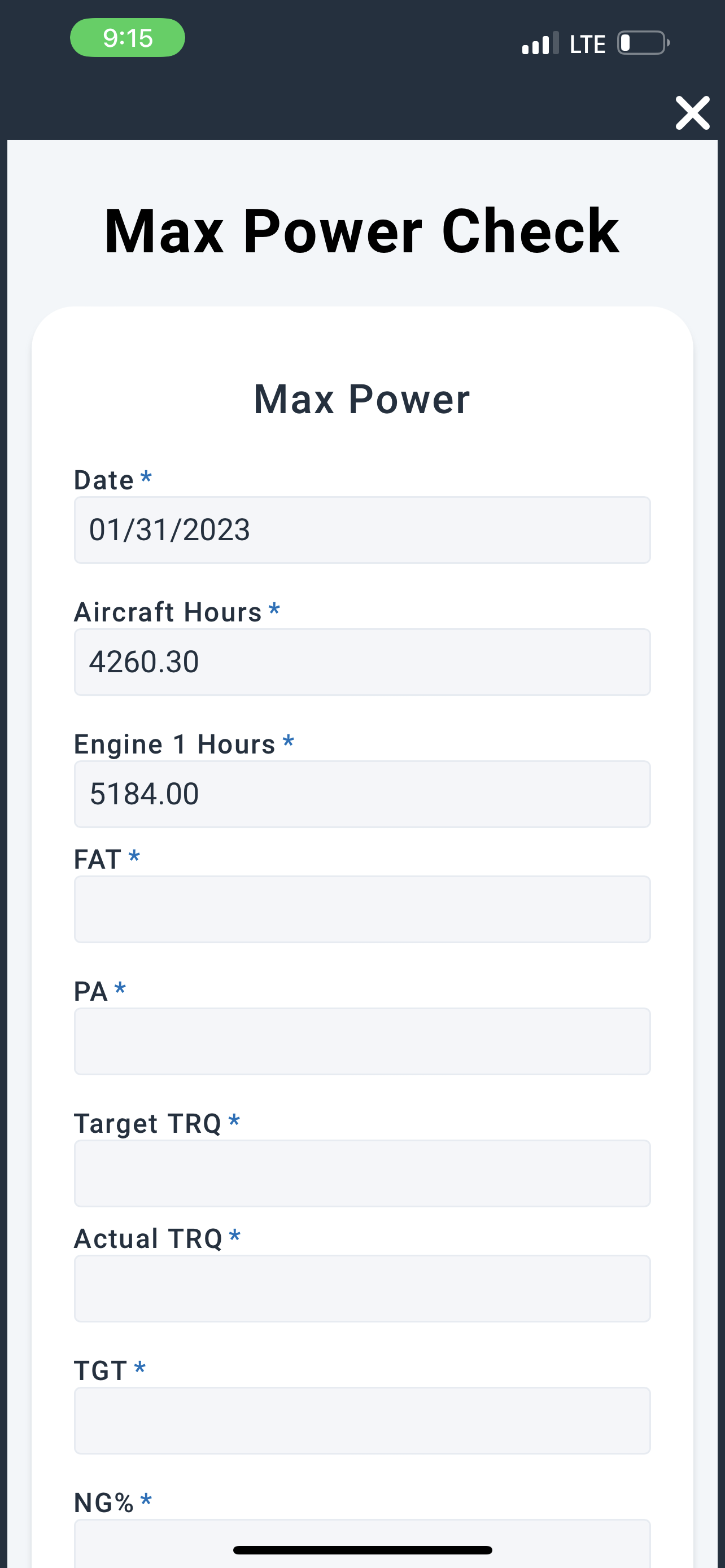

Select “Enter” under the Max Power section to pull up the Max Power entry page. Enter the environmental and aircraft performance data, Target Torque Value, and actual torque value noted during the check. As stated earlier, subsequent HIT checks parameters will synchronize with the latest HIT Baseline.

Field First

ModernHawk offers advantages in the field for operators looking for a field-ready maintenance tracking toolkit. ModernHawk’s ease of use allows pilots and program managers alike to quickly input or review engine performance data from any location on any web-enabled device. This capability increases visibility on potential negative trends that may be occurring in real time versus periodic reviews of paper HIT logs or solely relying on pilot-to-maintenance communication.

ModernHawk offers these and many more tools to clients looking for a “Field First” solution to their maintenance and operations process. Recent improvements include an updated Progressive Web Application with limited offline capabilities. Reach out to us anytime if you have any questions or would like a full demonstration on what ModernHawk can provide to your business.